- other_housesHome

- Professionals

- Technical Planning Documents

- Fiberglass Planning Documents

Fiberglass Installation Systems

New Construction

Fiberglass Methods of Attachment

There are many options for installing Pella® Impervia® fiberglass composite windows in new construction and renovation projects67

- Nailing fins

- Flanges

- Block frames with fins

- Masonry clips or jamb screws

Integral Fin

The integral fin design features a continuous fin, allowing the window frame to be integrated into the building's weather-resistant barrier using the Pella Window and Door Installation Method.68

This total installation solution includes our exclusive SmartFlash® installation tape and low-expansion, low-pressure polyurethane insulating window and door foam sealant.

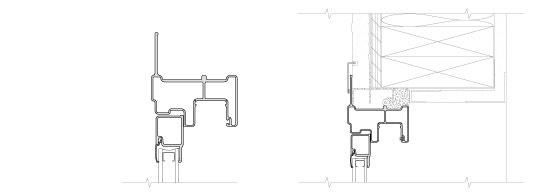

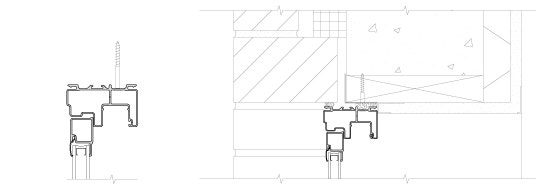

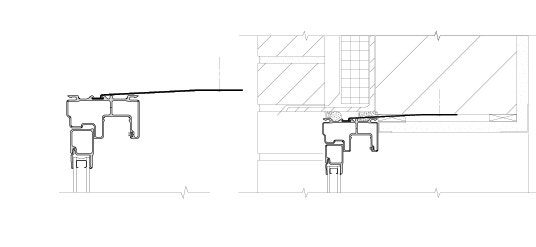

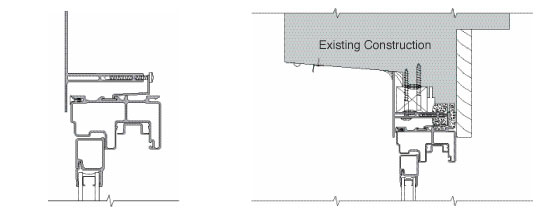

Block Frame

- The block frame provides a variety of attachment and installation options

- Windows can be installed in wood/steel frame openings using optional fins, or in masonry openings using installation clips or jamb screws

- Block frames may also be used in window replacement projects without removing the existing frame or damaging the exterior

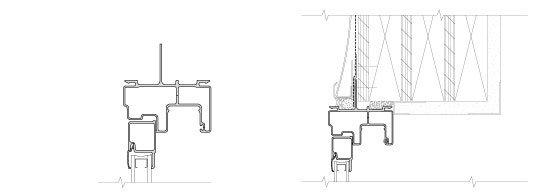

Block Frame with Offset Fin

- The continuous offset nailing fin is designed for use in new construction with thin exterior claddings like stucco, thus allowing the window to be located more to the interior

- When the offset is not required, a standard profile fin is available (Shown with dashed lines.)

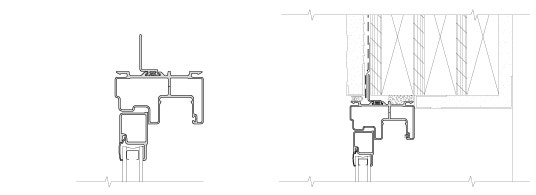

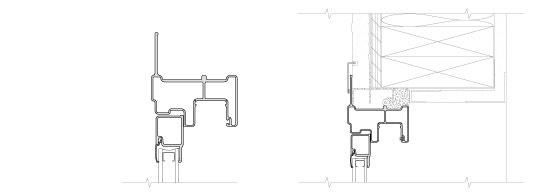

Block Frame with Installation Clip

For new construction or window replacement where wall conditions or construction sequence requires installation from inside the building.

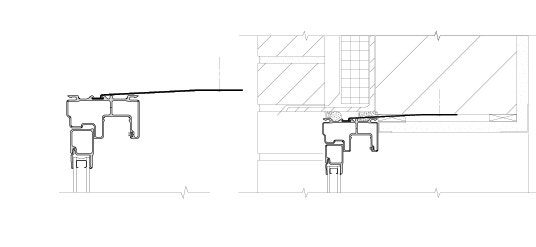

Block Frame with Screw Attachment

For new construction or window replacement where normal fin/tape installation cannot be accomplished because of wall conditions or construction sequence.

Receptors and Subsill

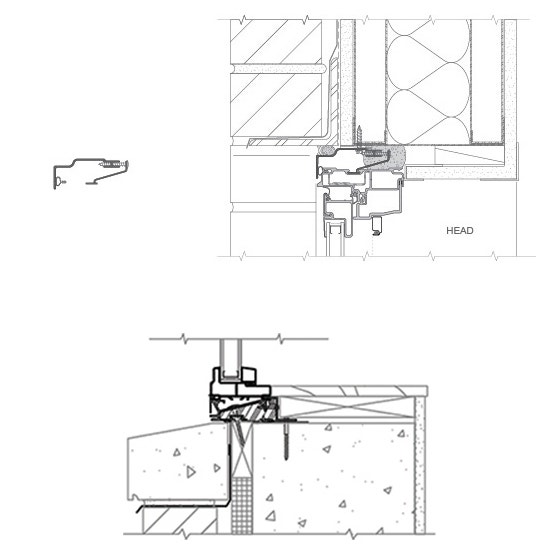

Receptors are used for multistory buildings requiring installation from the interior or when a more robust installation method is desired.

Fiberglass Punched Openings

A facade created by the orderly placement of single or multiple windows in punched openings in a wall can be a strong design statement. With Pella's wide range of sizes and product types, your punched-opening design options are virtually unlimited.

Design Recommendations

Depending on the number and configuration of windows and doors per opening, design recommendations for perimeter clearances, weight limitations, wind loads and water management may vary.

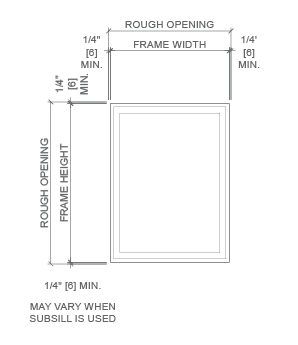

Perimeter Clearances

- To determine window opening size for typical installations, add 1/2" to frame width and height

- For large windows, multiple windows, out-of-plumb openings, and/or in masonry construction, the need for additional jamb clearances should be reviewed

Typical Sealant Recommendations

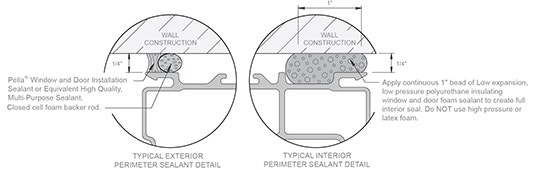

Proper sealant placement is critical to window or door performance.

When applying siding, brick veneer or other exterior finish material, leave adequate space between the unit frame and the exterior finish material for backer rod and sealant.Note: The sealant details shown are standard recommendations from the sealant industry. Contact your sealant supplier for recommendations and instruction for this or any other application.

Fiberglass Horizontal Ribbons

Ribbon windows are an important design element for buildings with sweeping horizontal lines. Pella fiberglass windows offer elegant solutions for virtually any ribbon application - and our technical staff can assist you with expansion/control and reinforced mullion details to reconcile your design objectives with functional requirements.

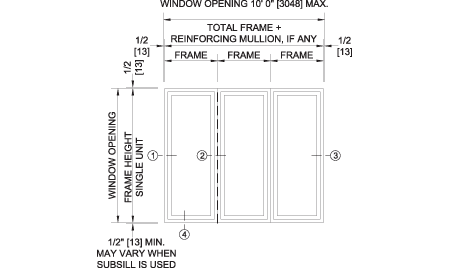

Typical Elevation

These recommendations apply to a typical horizontal combination of any vent or fixed unit.

- Minimum 1/4" clearance on smaller openings.

- Check if mullion reinforcement is required due to specified wind loading. Minimum 1/2" clearance is recommended at each jamb for openings with three or more windows.

- Proper sealant placement is critical to window performance.

- Subsill systems that weep incidental moisture to the exterior are recommended for water management in openings where the potential for water infiltration is increased and may not be adequately managed by the building weather barrier, flashings and drainage system. Sample conditions include, but are not limited to: increased level of exposure due to multi-story construction, high weather exposure, recaulking would be difficult or unlikely, non-standard installation methods, or when there are multiple units joined within the opening.

Subsill

.jpg?width=250&height=165&format=jpg&quality=90)

Subsill systems that weep incidental moisture to the exterior are recommended for water management in openings where the potential for water infiltration is increased and may not be adequately managed by the building weather barrier, flashings and drainage system.

Sample conditions include, but are not limited to:

- Increased level of exposure due to multi-story construction

- High weather exposure

- Recaulking would be difficult or unlikely

- Non-standard installation methods

- When there are multiple units joined within the opening

Fiberglass Vertical Stacks

When you want the visual impact of vertically stacked windows, the Pella Commercial technical staff can work with you to provide mullion reinforcement or intermediate dead-load support detailed to ensure compatibility with your aesthetic vision.

Design Recommendations

In addition to the recommendations for punched openings, the greater height of vertical stacks often requires special detailing, reinforcing mullions, intermediate dead load support, and subsills to resist structural loads, allow for construction tolerances, and provide adequate water management.

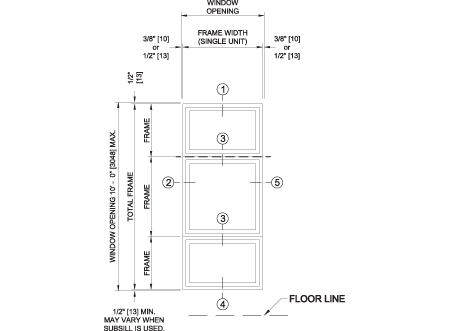

Typical Elevation

These recommendations apply to typical vertical stacking of vent or fixed units of the same width to a maximum height of 10' without intermediate support.

- Intermediate dead load support is required as needed.

- 1/2" clearance is recommended at each jamb for construction tolerances in large combinations.

- Check if reinforcing mullion is required due to specified wind loading and dead load.

- Subsill systems that weep incidental moisture to the exterior are recommended for water management in openings where the potential for water infiltration is increased and may not be adequately managed by the building weather barrier, flashings and drainage system. Sample conditions include, but are not limited to: increased level of exposure due to multi-story construction, high weather exposure, recaulking would be difficult or unlikely, non-standard installation methods, or when there are multiple units joined within the opening (See subsill detail below).

- Pella® Impervia® windows require stacked units to be mulled together using the combination mullion accessory prior to placing the windows in the rough opening. Practical consideration should be given to limiting the quantity of stacked units within a given height to an amount that can be safely handled by the installer without damage to the units and mullion integrity. The recommended number of units per stack is three or less.

Subsill

.jpg?width=250&height=165&format=jpg&quality=90)

Design Recommendations

- Intermediate dead load support is required for vertical stacks more than 10' in height

- Many solutions are possible, including those shown

- Recommendations on the Weight Limitations of Transoms over Doors

- Check local code requirements when stacking windows past floor lines

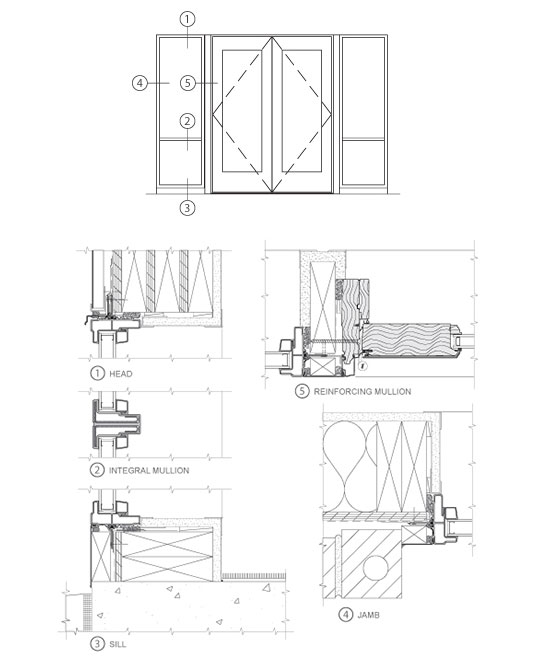

Entrances and Storefronts

Configurations that combine aluminum-clad wood entrance doors with fixed fiberglass windows at street level provide virtually infinite design possibilities for creating welcoming building entries.

Design Recommendations

Storefronts and entrances include a combination of windows and doors that often require reinforcing mullions, expansion mullions, and subsills to resist wind loads while providing adequate water management.

Typical Elevation

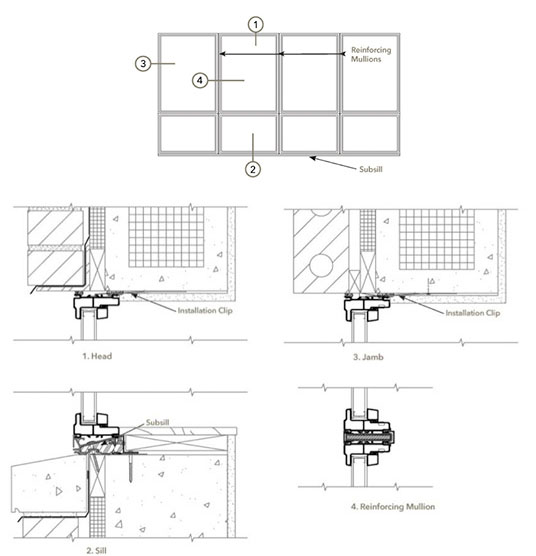

Fiberglass Window Walls

When your project requires the visual impact and energy efficiency of Fiberglass window walls, the Pella Commercial design team can partner with you early in the project to develop engineered fenestration solutions that meet your performance and load requirements without compromising your design vision. Plus, the beautiful wood interiors provide a unique design aesthetic.

Design Recommendations

Window walls may include a combination of windows and doors that require reinforcing mullions, expansion mullions, and subsills to resist wind loads while providing adequate water management.

Typical Elevation

Fiberglass Combinations (Mulling)

Specific accessories and construction details must address the various conditions that are critical for the proper design of combinations of windows and doors such as:

- Proper flashing

- Control joints to accommodate expansion and contraction

- Intermediate structural

- Mullion reinforcing and it's end anchorage to the rough opening

- Rough opening wall construction to accept loads transferred from window combination

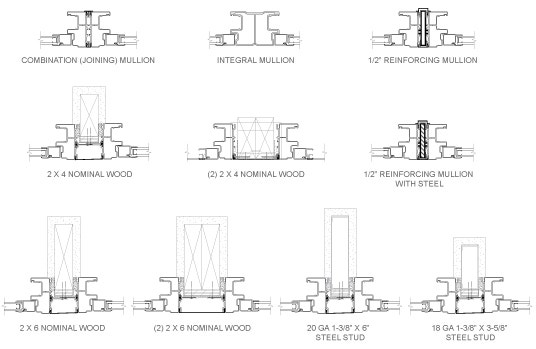

Mullion Design

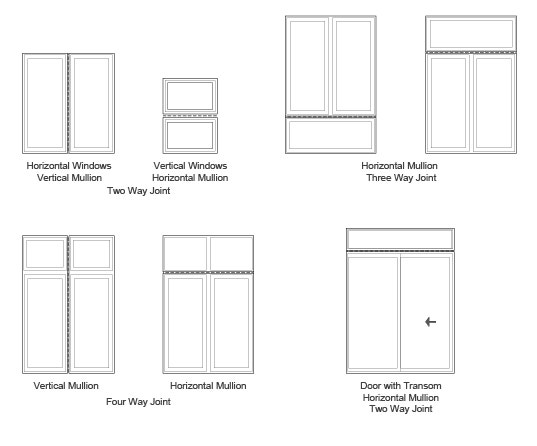

Placing windows and doors in a combination creates joints or mullions that may need structural reinforcing.

- Spread mullions can also be utilized to achieve an aesthetic element

- In order to ensure that a given combination will withstand the design pressure, use the reinforcing tables on the following pages

- These tables are organized by joint type and assembly type (factory vs. non-factory assembled)

- Use the graphical representation of each joint type to determine which joint type(s) are contained within the combination

- The reinforcing tables consider structural performance only

- See the Size and Performance Data page within each product section for single unit performance class and grade ratings

Important:

Determining and meeting the structural load requirements and design of the rough opening is the responsibility of the architect or engineer. Window and door frame systems are not designed to support additional elements or components of the building wall system.

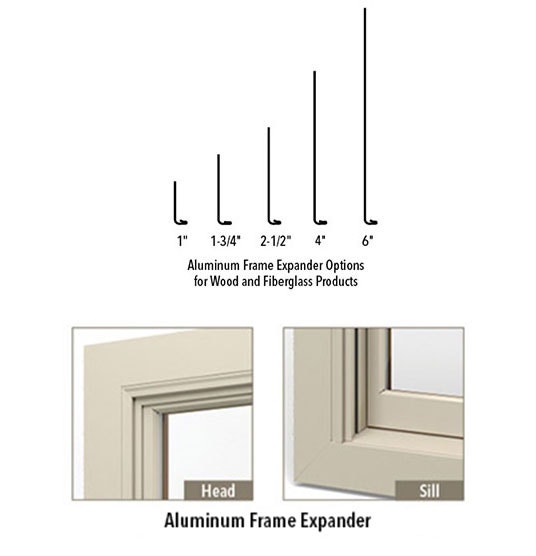

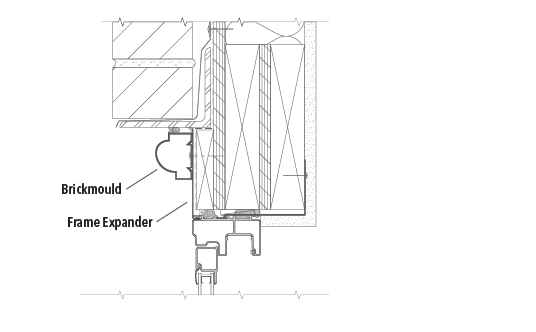

Frame Expander

Durable, snap-in trim that is adjustable to field conditions

- Prefinished; matches Pella products

- Provides the look of flat trim

- Aluminum brickmould can be attached to re-create the look of historical wood brickmould

- No metal brake required

- Cut-to-length kits, 96" or 144" lengths

- Available in widths from 1" to 6"

- Receptors are available to provide a finished edge

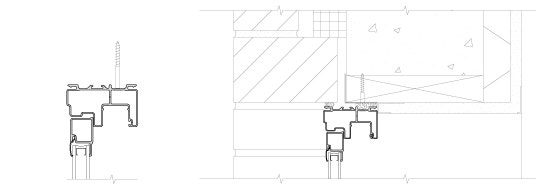

Aluminum Brickmould with Clip

Head Detail

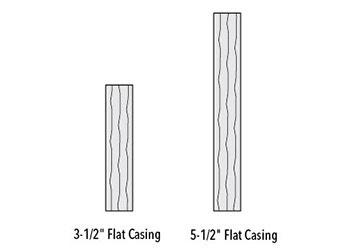

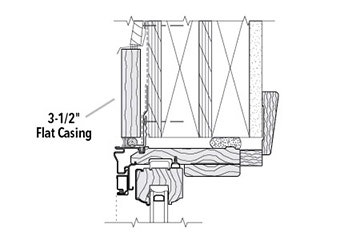

Rough/Smooth Wood

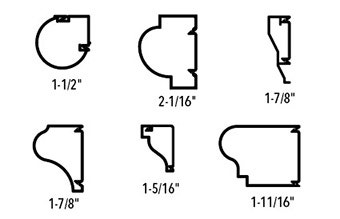

Field-cut, protected, reversible wood trim

- Primed and ready for site finishing

- Grained or smooth appearance

- 10' lengths

- 3-1/2" or 5" flat widths, 3/4" thickness

Trim Profiles

Head Detail

Renovation

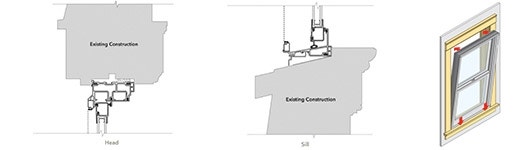

Complete Tear-out of Existing Frame and Sash

Depending on the needs of the project, fiberglass windows can be used to replace existing wood or metal windows when a complete tear-out of the existing frame and sash is required.

Block Frame with Screw Attachment

Block Frame with Installation Clip

Flush Flange

- The flush flange frame is designed specifically for replacement applications on stucco exteriors in arid climates like those found in the southwestern part of the United States

- The flush flange allows for quick installation without removing the existing frame or damaging the stucco exterior

Renovation Retain Existing Frame and Replace Sash

In contrast to the complete tear-out approach, the more commonly used approach to window replacement recognizes that the frame and trim that is already installed in the exterior wall may still be fully serviceable, but the operable or fixed sash may need replacing.

- It saves on the labor costs associated with the complete tear out approach, but also assumes that other considerations can be met through the re-use of the existing frame and trim

- Reuse may enhance historic or maintenance considerations depending on the project

- Pella offers a variety of installation systems designed to accommodate this approach

Pocket Installation

For window replacement when the existing frames are in good condition and only the sash needs to be replaced.

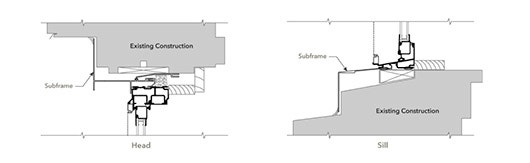

Standard Subframe System

For window replacement when wood windows are being replaced with fiberglass windows.

Block Frame with T-Subframe

For window replacement requiring installation from inside the building, Pella's T-subframe system reduces labor costs by eliminating the need for exterior scaffolding.

Flush Flange